I also have a modest collection of their now sadly out of production Target loaders wich feature the old Lee hand primer without the primer tray, much beloved by bench rest shooters for its legendary feel, they also have included in the kit an inside neck reamer for bullet concentricity along with the OAL length adjusting part being marked for micro adjusting.

Set up ready to go.

For throwing the powder I use a Ohaus Duo Measure mounted in my redding T7 press.

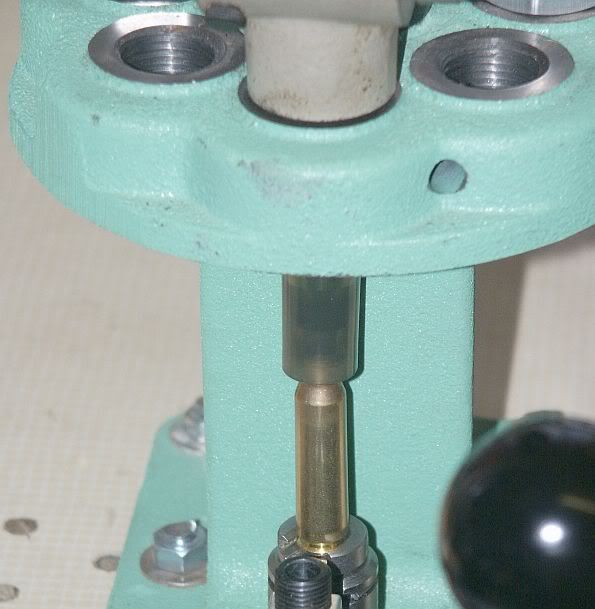

Step 1 Depriming the fired and cleaned case.

Setting the case in the depriming base.

Inserting the depriming rod, you need to feel the decap pin entering the flash hole.

Knock out the primer with a brisk tap of the soft faced hammer. I set the base over a bolt hole in the bench and the primers drop though to be collected in a plastic container on a shelf underneath.

Step 2 neck sizing.

The case is dropped into the die body.

Drive the case into the die with the hammer 'till the base is flush with the die.

Step 3 Priming

Some people have had primers go off during this stage, its not really a problem if you keep your hand away from the top of the die body and wear safety glasses, its just a bit discorncerting. I radius the primer pocket slightly with a deburr tool and have found that this prevents primer detonation.

Putting the primer in the priming base.

Locating the case still in the die body over the priming base.

Inserting the priming rod.

A tap with the hammer.............

...........and a perfectly seated primer.

Step 4 Removing the case from the die.

With the priming rod still in place put the die onto the decapping base.

Tap out with the hammer but leaving the case in the die.

Step 5 throwing the powder.

Measure is set up to dispense the desired charge.

I use a fired cartridge here for transferring the powder, nowadays I'd trickle up with my Target Master and scales.

Check the powder level in the case.

Place the powder funnel in the top of the die body and decant the measured charge into the case through the die.

Step 6 seating the bullet.

The bullet seating depth is adjusted by turning the top part of the die body in or out to give the desired seating depth/OAL.

Removing the funnel from the die pick up a bullet and drop it base end first thought the hole in the top of the die.

Insert the seating tool rod into the die after the bullet.

Tap with the hammer 'till the seating tool meets the top of the die, almost there.

Lift the die body of the round and there you have it a perfectly crafted 308 cartridge and a happy hand loader.

Time to load 50 rounds with care 70 minutes.