Bearing Surface Comparator.

Moderator: dromia

Forum rules

All handloading data posted on Full-Bore UK from 23/2/2021 must reference the published pressure tested data it was sourced from, posts without such verification will be removed.

Any existing data without such a reference should be treated as suspect and not used.

Use reloading information posted here at your own risk. This forum (http://www.full-bore.co.uk) is not responsible for any property damage or personal injury as a consequence of using reloading data posted here, the information is individual members findings and observations only. Always verify the load data and be absolutely sure your firearm can handle the load, especially older ones. If in doubt start low and work your way up.

All handloading data posted on Full-Bore UK from 23/2/2021 must reference the published pressure tested data it was sourced from, posts without such verification will be removed.

Any existing data without such a reference should be treated as suspect and not used.

Use reloading information posted here at your own risk. This forum (http://www.full-bore.co.uk) is not responsible for any property damage or personal injury as a consequence of using reloading data posted here, the information is individual members findings and observations only. Always verify the load data and be absolutely sure your firearm can handle the load, especially older ones. If in doubt start low and work your way up.

-

spud

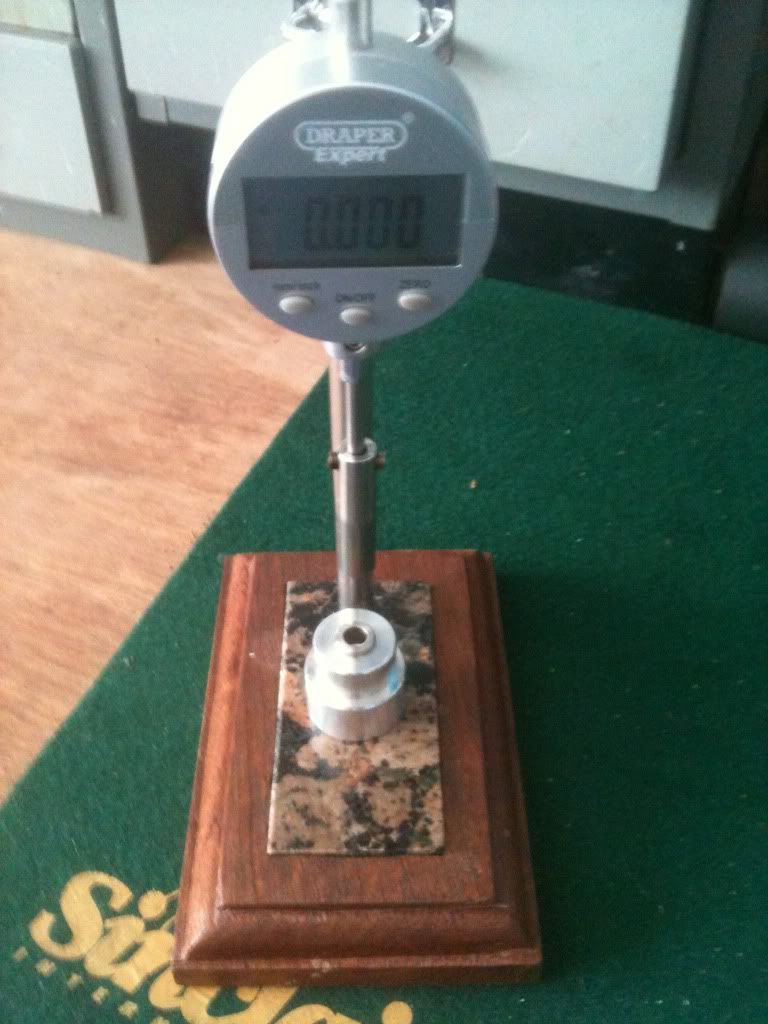

Bearing Surface Comparator.

Having had a look round the net for bearing surface comparator (BSC) for a while now and to be honest not found much that floated my boat. Any way after speaking to ovenpaa on here who has been making the odds bits and peices for me for a while now, we decided why not make our own. Watch the vid here then read on....

Having had the comparator over the weekend now ive been able to use and test and evaluate the BSC on over 800 7mm Berger VLD's.

My finding's are thus

Betwean the lowest and highest reading there was over 9 thou difference in bearing surface length, now all these bullets were ALL the same LOT number and came in the packaging.

The tips broke down to these groups

176 number @ 0.000

256 number @ +0.003

358 number @ +0.006

112 number @ +0.009

Now looking at these numbers you will say "0.000 how can that be" but remember these are comparisons of length in relation to each other and NOT actuall physical length's.

You will ask "why bother with all this BS" i say if the tips bearing surface are this much out, for extreme consistant performance and consitancy its a must do procedure.

Discuss!!!!

Having had the comparator over the weekend now ive been able to use and test and evaluate the BSC on over 800 7mm Berger VLD's.

My finding's are thus

Betwean the lowest and highest reading there was over 9 thou difference in bearing surface length, now all these bullets were ALL the same LOT number and came in the packaging.

The tips broke down to these groups

176 number @ 0.000

256 number @ +0.003

358 number @ +0.006

112 number @ +0.009

Now looking at these numbers you will say "0.000 how can that be" but remember these are comparisons of length in relation to each other and NOT actuall physical length's.

You will ask "why bother with all this BS" i say if the tips bearing surface are this much out, for extreme consistant performance and consitancy its a must do procedure.

Discuss!!!!

- 20series

- Full-Bore UK Supporter

- Posts: 4941

- Joined: Mon Nov 08, 2010 10:42 am

- Home club or Range: Oundle R&PC

- Location: Chelveston, Northants

- Contact:

Re: Bearing Surface Comparator.

Spud

Good video mate :goodjob:

Another interesting variable to consider, I think I might be interested in one for the .308

I had a look yesterday when I was over at Christel and Ovenpaa's place.

Alan

Good video mate :goodjob:

Another interesting variable to consider, I think I might be interested in one for the .308

I had a look yesterday when I was over at Christel and Ovenpaa's place.

Alan

A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools!!

Douglas Adams, 1952-2001 RIP

Douglas Adams, 1952-2001 RIP

Re: Bearing Surface Comparator.

Thanks for the review Spud, it is always nice to see something I have built being used. Spud and I talked about this a lot and discussed many different design options, he supplied the granite and we both agree it would look nicer and be more stable if the granite was let into a block of wood. Also I will change the angle of the mouth of the comparator top on the next one. Hardest part was finding out how close to the nominal .284" bullet diameter I could get with out the bullet disappearing up the hole! (it did on the first couple I made....)

Anyway to the theory behind it.

I did a very rough measure of a 180 VLD bearing surface and make it around .556" (I haven’t built another BSC to confirm this so it is an approximation) this would mean a variance of 1.6% on the bearing surface length.

We usually aim to load our powder to +/- .1 grains which on a 50 grain load is 0.2% so why not take the same time on the bearing surface which left unchecked gives a significantly higher percentage error.

Interesting stuff, especially as the Berger's Spud tested were all from the same batch so from the same machine.

Anyway to the theory behind it.

I did a very rough measure of a 180 VLD bearing surface and make it around .556" (I haven’t built another BSC to confirm this so it is an approximation) this would mean a variance of 1.6% on the bearing surface length.

We usually aim to load our powder to +/- .1 grains which on a 50 grain load is 0.2% so why not take the same time on the bearing surface which left unchecked gives a significantly higher percentage error.

Interesting stuff, especially as the Berger's Spud tested were all from the same batch so from the same machine.

-

Dougan

Re: Bearing Surface Comparator.

Makes sense - We KNOW consistency is key...so why not take it all the way

It would be interesting to make some of the best rounds you can (which I believe is a specialty of you guys), then try different batches off bullets through a chrono...although I'm sure this is already part of the plan :)

It would be interesting to make some of the best rounds you can (which I believe is a specialty of you guys), then try different batches off bullets through a chrono...although I'm sure this is already part of the plan :)

-

spud

Re: Bearing Surface Comparator.

Thanks for the comments guys and a very big thank you to Dave for the outstanding work and all off the time he put in to this product, i hadnt seen the David Tubb version un till we were half way through this project, its similar but not exactly the same andits also nice for him to confirm what both Dave and I thought about this system/ and actually how much this segrgation would make.

-

spud

Re: Bearing Surface Comparator.

Yes the loads will be put over/through a chrono, at this moment in time all my case/bullet prep is leading up to a new rifle coming home in the next couple off months,Dougan wrote:Makes sense - We KNOW consistency is key...so why not take it all the way

It would be interesting to make some of the best rounds you can (which I believe is a specialty of you guys), then try different batches off bullets through a chrono...although I'm sure this is already part of the plan :)

Once that is here i can either confirm yey or ney if this experiment has worked.

All bullets have been previously weight sorted and will be further sorted by ogive diameter seating depth.

-

Dougan

Re: Bearing Surface Comparator.

I like the wood and marble - would look good on the bench  ... and more stable now

... and more stable now

Who is online

Users browsing this forum: No registered users and 7 guests