meles meles wrote:oomans: The L85 as designed was a great bit of kit. Machined from solid steel, of a good quality, accurate and reliable. The Treasury baulked at the cost and passed it to the ROF (then owned by BAE) with instructions to 'value engineer' it. Forgings and machined parts were replaced by pressed metal stampings, spot welding and plastic. The cost reduction was enormous, in the short term at least. For the next decade or two it fell apart and even greater sums of money were spent on getting it to be reliable again. Eventually, it was built almost to pattern and reincarnated as the A2 version.

The L85 as designed was always intended to be built upon a stamped receiver albeit I concede there might of been more forged sub components. There was also certainly a 'value engineering' exercise when the weapon was productionised but it certainly wasn't a great piece of kit beforehand. Enfield made a number of mistakes in executing the design being more used to machined receivers and wood rather than stamping and plastics. The 4.85x49mm XL64 and XL65 prototypes (forerunner of the L85) had over 700 incidents of poor reliability logged in trials. There were numerous mechanical failures, failures to feed, failures to extract, failed spot welds and trigger seer problems. These problems continued into the reworked XL70 prototype that was developed when the SS109 round won NATO standardisation trials.

Enfield XL64

Enfield XL64

Which then leads me onto the most sordid aspect in the story of the SA80's development. The Sterling Armament Co. Ltd at Dagenham had as already has been observed been building the AR-18 under licence which the SA80 is derived from. Stan Carroll, then the Director of Small Arms at RSAF Enfield asked to visit the Sterling factory to see the production techniques that went into making the AR-18. The general manager of Sterling David Howroyd and James Edmiston the owner agreed as they thought there was a good chance at getting subcontractor work.

Here is a quote from an old Observer article if what happened next:

"In 1976 Edmiston and his designer, Frank Waters, saw the prototype SA80 at the British Army Equipment Exhibition in Aldershot. It was a bullpup design, a squat rifle with a minimal butt, and its operation looked curiously familiar.

'Frank was allowed to take it apart,' Edmiston told The Observer. 'He found our bolt carrier, our magazine, and parts out of our gun. These weren't even copies. They had bought some of our guns and were using the parts to make the SA80 prototype.'

A former weapons designer with Royal Ordnance confirmed that claim. He added that the original prototypes, basically an amalgam of the Armalite AR18 and the bullpup design of the old RO EM2 were good, promising guns . . . 'but the design was fiddled with by committees in the MoD and Royal Ordnance.' The gun, he says, has never been the same since."

"Not once did Enfield ever ask Sterling for information on the AR18 . . . I know of at least one component that they 'copied' incorrectly which could well have made a difference to reliability."

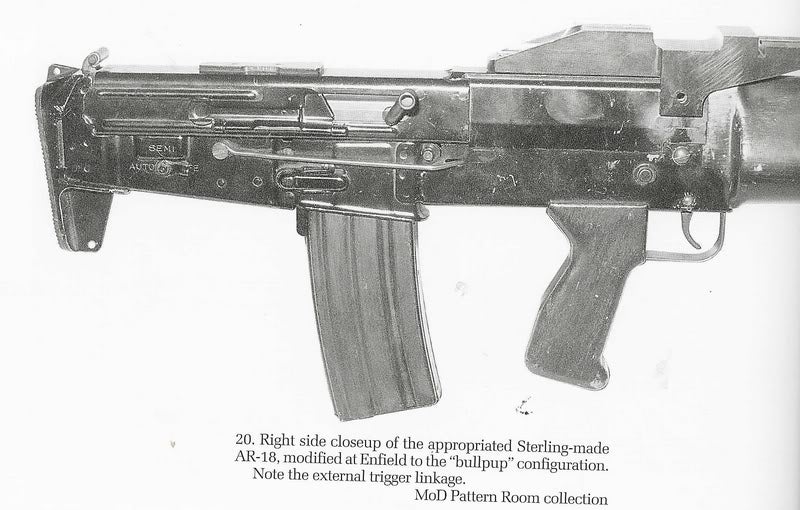

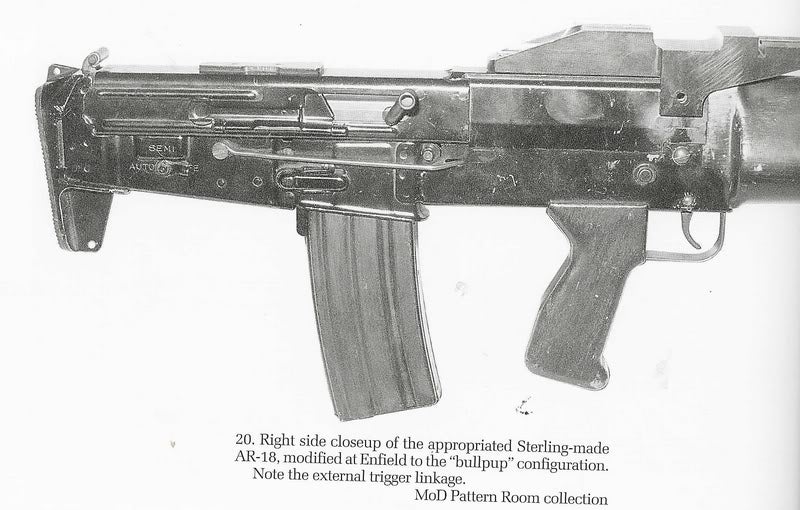

The first proof of concept prototype that proceeded the XL64 didn't just canibalise components out of the Sterling Built AR-18 but was actually a commercially purchased Sterling AR-18 reconfigured into a bullpup, the picture below speeks a thousand words IMHO:

Sterling were so irritated they mocked up a joke mock up bullpup version of their AR-18 make their point of how they had been robbed.

The irony is if Enfield had brought Sterling in on the project as a sub contractor they could probably of avoided many of the issues the SA80 suffered. Instead Sterling went Bankrupt with the government compulsory purchasing the factory with the singular aim of shutting it down.